Blog

Everything you need to know about AC Compressor Failure

AC compressor failure is a common problem and can be caused by some very common issues. The good news is that these issues do not require a major overhaul. Here is a closer look into the nuances of AC compressor failure.

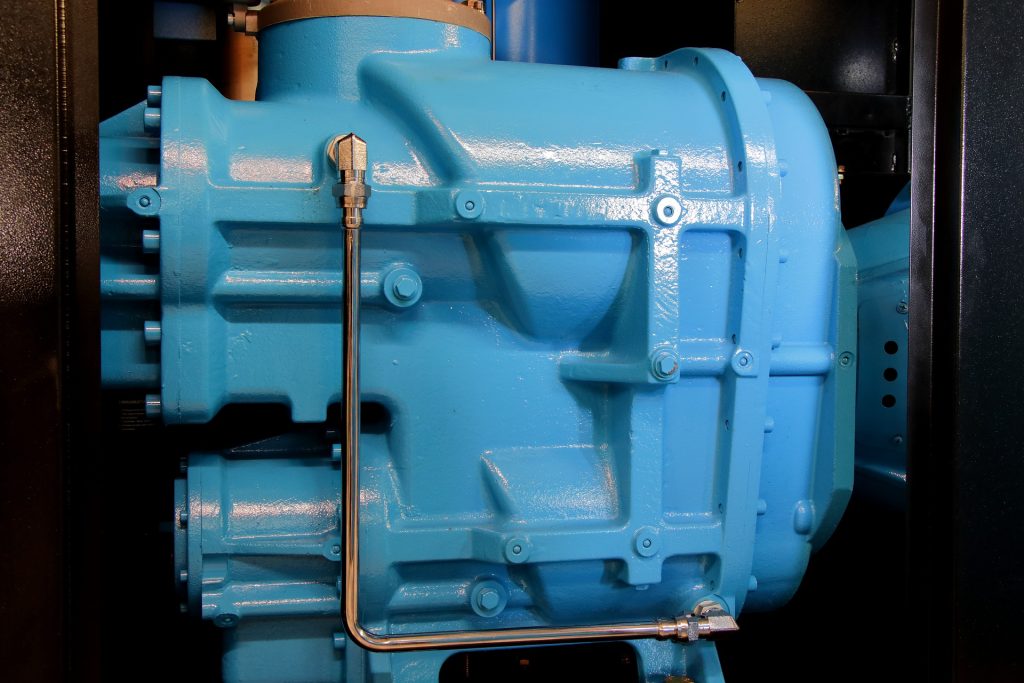

First, it is important to understand the function of an AC compressor. It is the component that makes the air conditioner function and without it, an AC unit won’t be able to work. A typical AC compressor is expected to last 10 to 15 years and serves the function of pumping compressed refrigerant gas throughout the unit. Its main job is to ensure the compressed air is free from humidity.

Reasons for AC compressor failure

Here is a look at the most common reasons an AC compressor winds up failing:

- Excessive among of refrigerant

- Dirty coils

- Clogged suction lines

- Electrical issues

- Presence of contaminants

- Wrong size suction lines

- Refrigerant charge is low

- Not enough oil lubricant

AC Compressor issues

If your compressor is low on Freon, it is not advisable to keep it running. When an AC unit has a low charge, it puts an added strain on the coil, which will limit its absorption capabilities. Low refrigerant can also increase the chances of overheating and cause damage to the compressor.

Compressors are also susceptible to burnout and this is often a result of motor winding temperatures that are too high. The excess temperatures break down the insulation in the motor winding and can lead to a short.

There is not always one element that can contaminate a compressor. A system can fail due because of contamination from air, acids, and dirt, which are created by the pressure and heat within a compressor. Meanwhile, electrical failures are generally a result of voltage imbalances.

Be mindful of your compressor

Most people are not aware of the proper ways to maintain an AC compressor, although that is important to maintaining its expected lifespan. Preventative maintenance provided by a professional compressor service is recommended and can ensure that your AC unit will provide years of top-notch performance. The recommended service schedule for an AC compressor is twice a year. More than 75 percent of compressor problems are avoidable and could be something as simple as a clogged filter.

If you are experiencing any kind of issues with your AC compressor, contact the team of experienced pros at City Compressors. We have a vast selection of parts plus the best remanufactured compressors nationwide.

Common Compressor Issues and How to Fix Them

It is not uncommon for a compressor to fail as there are a multitude of reasons that could lead to a malfunction. Some malfunctions are simpler to avoid than others, although there are some breakdowns that are inevitable. That doesn’t mean every problem has to be a major one. Here is a look at some of those issues and how to keep them from destroying your compressor.

Upkeep

Because of the economy, not every budget has enough room for preventative maintenance. Therefore, it is understandable as to why some businesses pass on this aspect of service. It is also important to note that evaporators and condensers can accumulate dirt. When either of these parts get too dirty, your system will be unable to charge.

Wear and tear

Constant use will cause belts and pulleys to wear out over the course of time. Adjustments will need to be made and this can even be done without the service of a professional. Other components can also fail and that could lead to other problems. For example, failing to change a bad relay will burn out the motor.

Keep an eye out

Refrigerant needs to always be charged or else the system could incur icing, which can severely damage a compressor. Meanwhile, a valve that is not properly adjusted will damage the compressor and could cause a liquid floodback. This issue can be alleviated by the quick and easy process of making sure the filter is clean and also doing a check on the super heat.

- To make things even easier, here are some simple steps to follow. Compressors are an important component and keeping them functioning properly can be accomplished by adhering to these guidelines:

- Be sure to examine the gauge pressures. These should be operating on a normal level according to the specified box temperature and ambient.

- Run a visual sweep of numerous components, including the oil level and amp draw. As a rule, the compressor should feature 20 degrees.

- Whenever a compressor is replaced, it is a good idea to also replace the driers as well as the contactors A failure to do so could shorten the lifespan of your new compressor.

- Get to know your oil. It is vital to match your refrigerant with the proper oil. There are far more refrigerants to choose from than oils, which are limited to only a few. Mismatching refrigerants and oils could bring about big problems.

Dispelling the Myth of New Semi-Hermetic Compressors

Those in the market for a new semi-hermetic compressor have options, but they may be less abundant than consumers tend to realize. Compressor remanufacturing has become big business and is also the norm. That has led to the term OEM (Original Equipment Manufacturer) taking on new meaning.

When it comes to compressors, OEMs remanufacture their semi-hermetic compressors. It is the same process used here at City Compressors. The lone exception is Carrier/Carlyle, which do feature brand new semi-hermetic compressors that are included on new package units. However, there are ample reasons as to why remanufacturing has become the norm for semi-hermetic compressors.

There are many common issues with semi-hermetic compressors as they are prone to oil leakage, inadequate levels of coolant, overheating, contaminants, and improper setting of valves. It is difficult to avoid some of these issues, especially ones where outside contaminants infiltrate the system and flood the compressor. While not all these problems cause an immediate shutdown, they can take a toll over periods of and reduce performance.

To the untrained eye, it remains difficult to detect subtle problems with a semi-hermetic compressor. As these systems have grown, all the components have become more complex, making it more difficult to identify smaller issues. But not all those issues are going to cause the compressors to cease. Some minor issues may simply bring about the need for troubleshooting. This is where the remanufacturing process becomes more financially viable.

The benefits of remanufacturing also generate much less downtime. A full replacement would mean more time lost. Companies, such as City Compressor, have all the necessary parts to provide a customized rebuild. Furthermore, the process is able to remain the same as semi-hermetic compressors are not undergoing wholesale changes. That is also a financially reassuring notion for business owners.

It is never out with the old and in with the new when it comes to semi-hermetic compressors. New is a relative term in this industry, one that has led to common misconceptions. Semi-hermetic compressors can continually be serviced, making them a very unique item. It is a rarity in the modern age that such a powerful and widely-used contraption can be upgraded, fixed, and adjusted over long stretches of time.

This gives credence to the marvels of the remanufacturing process and has made the term OEM a bit obsolete when shopping for semi-hermetic compressors. City Compressors can provide a remanufactured semi-hermetic compressor that will work as good as any you will find on the market.