Our Process

Follow our total remanufacturing process from start to finish

Overview

Overview

1

Disassembly

2

Cleaning

3

Requalification

4

Stocking

5

Motor

6

Assembly

7

Testing

8

Finishing

Overview Video

Disassembly

Complete disassembly and preparation of parts

- Each compressor is completely broken down into its component parts

- Parts prepped for cleaning

Cleaning

Multi-stage cleaning process of all components

- Ultrasonic degreasing

- Vibratory surface conditioning

- Thermal grease and oil burn off

- Shot blasting – steel and glass bead

- Parts resurfacing, grinding, lapping, polishing, and sanding

- Pressure washing and heated detergent

- Rust inhibiting

Requalification

Total component requalification

- Visual inspection of each component

- Gaging to specifications

- Machining cylinders to specifications

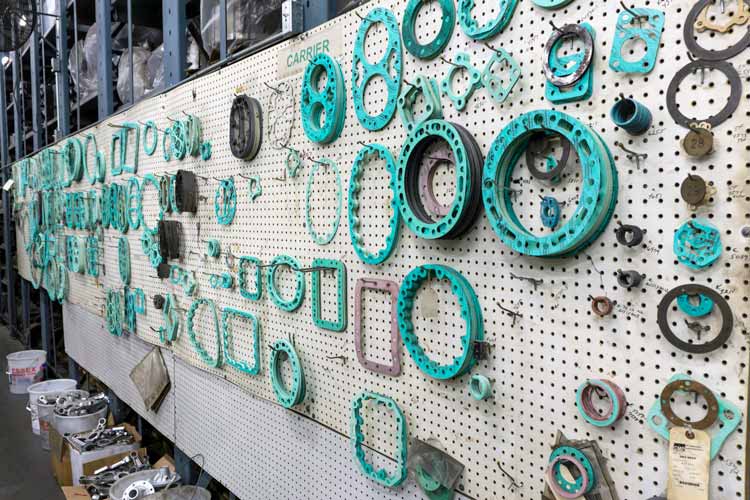

Stocking

Strategic stocking of components

- Buffer stock for quick assembly and delivery

- Large spare parts inventory

Motor Department

Motor assembly and testing

- Full service motor remanufacturing department

- Strip and clean all stators that do not pass requalification testing

- Stators are core loss tested

- New coils wound, installed in a requalified stator, connected for desired voltage

- Newly wound stators are stringently tested prior to varnishing and baking

Assembly

Compressor assembly and quality control

- Flexible final assembly line for quicker delivery

- All parts are again quality checked

- Five Q.C. stations on assembly line

Testing

Final unit testing

- Pressurized submersion leak test

- Electrical ground fault testing

- Hi-Pot testing

- Full load compressor run testing

- Evacuation and dry nitrogen holding charge

Finishing

Painting and packaging

- Spray painting with OEM-matched oil-based enamel color

- Gasket kits, labeling, and instructions provided with each unit

- Final quality checks made before being boxed for shipment